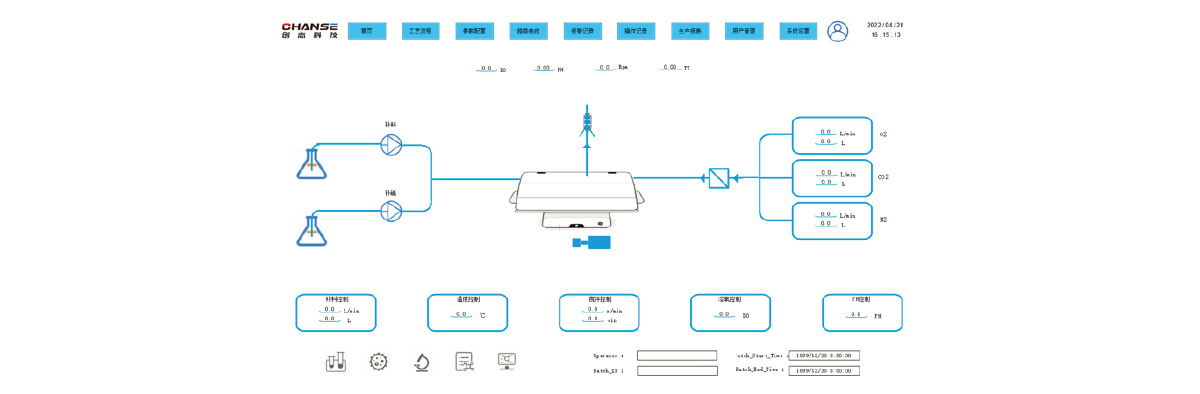

| Performance |

WAVE |

Mixing tank |

Spinner Flask/Shake Flask |

| Comparison |

| Mixed mode |

Wavy |

Immersion stirring |

Swinging vortex type |

| Shear force |

Extremely low |

High |

Low |

| Oxygen transfer area |

High |

Middle |

Low |

| Oxygen transmission mode |

Surface wave type oxygen transfer |

Bubbling oxygen transfer |

Surface oxygen transfer |

| Oxygen transmission effect |

High |

Middle |

Low |

| Dissolved oxygen level |

High |

Middle |

Low |

| Gas flow meter |

High precision mass flowmeter |

Cheap rotameter,low accuracy |

NA |

| Cell density(cell/mL) |

High density,generally >106-7 T CELL perfusion 1~2x107

Insect cell perfusion >108 |

106-7 |

Low density,generally1055-6 |

| Cross contamination risk |

NA |

High |

High |

| Infection probability |

Low |

Middle |

High |

| Cluture parameter control |

Automatic feedback regulation pH,DO,Temp, CO₂% |

Automatic feedback regulation pH,

DO,Temp, CO₂% |

NA |

| Weighing perfusion |

Integrated weighing and automatic filling |

NA |

NA |

| Working volume |

Flexible,10-100% |

Inflexible,50-100% |

Inflexible,10-30% |

| Foam |

Positive pressure,not easy to produce foam |

Large amount of foam will be

generated,and a defoamer is required |

Less foam |

| Operation |

Easy |

A lot of experience needed |

Difficult to scale up applicable |

| Microcarrier technology |

applicable |

applicable |

NA |

| Micro carrier ball |

It can be performed directly in the Wave without a digestion reactor |

The operation is complicated and needs

to be transferred to the digestion reactor. |

/ |

| Training environment |

Ordinary |

Clean room |

Clean room |

| mobility |

Yes |

Fixed |

Yes |

| Comparison of process scale-up production |

| Scale up mode |

00mL-100L requires only one WAVE,

or multiple 100L WAVES for parallel scale up |

Three to four seed tanks are required

for step by step to above 1000L. |

Large amount of spinner

flasks/shake flasks |

| Scale up |

Easy,fine tune parameters |

High risk,need to explore again |

Difficult to scale up |

| Equipment cost |

Low |

High |

Low |

| Computer real-time monitoring |

Yes |

Yes |

No |

Multi variety R&D and

production platform |

Sterile closed piped platform

enables quick change of cell

bags for easy authentication. |

Difficult to clean and certificate,

and cross contamination among varieties |

Difficulties in

managing certification |

| Equipment maintenance cost |

Low |

High |

Low |

| Cost of new workshop |

1(Class 10000 trolley room) |

10(Class 100 medium workshop) |

4(Class 10000 workshop) |

Expansion and utilization

of existing workshops |

No reconstruction required |

Redesign and build |

Extension |

| Workshop construction |

Short cycle and low cost |

Long cycle and high cost |

Long cycle and high cost |

| Production cycle |

Short |

Long |

Short |

| Fixed stainless steel pipe connection |

No |

Yes |

No |

| Production flexibility |

High |

Low |

Low |

| Auxiliary production cycle |

Short |

Long |

Long |

| Plant utilization rate |

High |

Low |

Low |

| SIP steam |

No |

Much |

No |

| WFI dosage |

Very little |

Much |

Middle |

| Cleaning and maintenance cost |

Extremely low |

Very high |

High |

| Consumables |

Cell bags(Cell bags of the same cells can be reused) |

Mixing energy consumption,

pipe sealing,valve gasket,

cleaning solution,WFl,SIP steam |

Cell flasks,cleaning

solutions,WFI and

extensive manual work |