An industrial revolution: Batch to Continuous

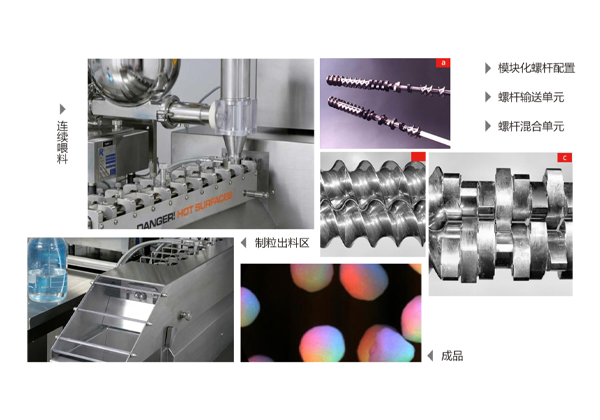

Continuous granulation is a production mode that tightly connects each step of product manufacturing in sequence, from raw material inputs to final product outputs, in accordance with process requirements. It is a production mode in which raw materials are continuously fed into the system while the terminal system constantly produces finished products.

- Combined with PAT to realize digital R&D, improve R&D efficiency and save R&D costs

- Optimize for scale-up with less risk, reducing duplicate equipment investments.

- Continuous manufacturing, automatic material transferring, higher production yield and lower labor cost

- Reduce facility space and capital costs with smaller, efficient equipment footprints

- Continuously monitor drug quality throughout the entire process and ensure the data is consistent, true, complete and traceable.

- Increase process flexibility and ability to react to changing market needs